Quality Assurance

Ensuring that every part produced conforms to our customer’s requirements and specifications is at the core of China Surgical Tools’s Quality Policy and integral to our success and trustworthy reputation in the Medical, Surgical, Aerospace and High Technology industries.

China Surgical Tools’s robust quality system provides full lot traceability. Complete documentation can be provided including material and process certifications, first article inspections report, lot inspection data, etc. China Surgical Tools’s engineering team designs innovative functional gauging to provide lean and foolproof in-process part inspection.

Our rigorous commitment to providing high quality components relies on our implementation of conformance validation measures throughout every process of part production.

Inspection and Quality Assurance Services:

- Meticulous Receiving Inspection

- 1st Piece Inspection Reports and In-Process Inspection

Inspection entries are made at the machine in real time by station operators to improve data accuracy and production efficiency and minimize scrap waste.

- First Article and Qualification Reporting

- Records of Process and Product Conformance

Preparing Inspection Data, Test Reports, Certification of Conformance for Material, Processes and final product in accordance with customer and regulatory requirements.

- Tight Control and Maintenance of all Process, Inspection, Testing and Measuring Equipment

China Surgical Tools monitors and maintains current maintenance and calibration of all production and inspection equipment through use of the web-based SimpleTrak(R) system by ION Quality Systems.

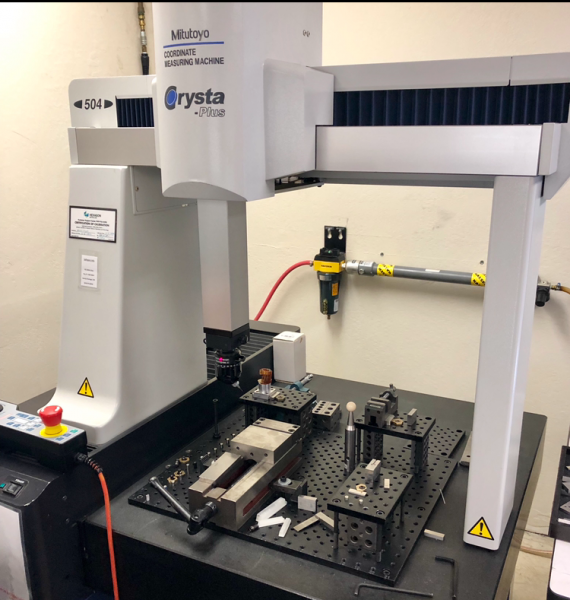

- State of the Art Inspection and Data Collection Equipment

China Surgical Tools’ automatic CMM utilizes the powerful PC-DMIS software to program the inspection of complex part geometries directly from customer’s solid model part files, and allows for fast and repetitive inspections at a low cost.

CMM Automation enables us to keep a close eye on the quality of part as they are machined; then provides quick feedback to manufacturing to improve the process. Detailed inspection reports are automatically stored on China Surgical Tools’s secure network.

- Control of Non-Conforming Material

- Nonconformance Accountability

- Root Cause Analysis and Corrective Action Implementation

China Surgical Tools employs an immediate accountability approach for nonconformances identified within each process operation. Using our web based SimpleTrak(R) nonconformance tracking system, our quality team identifies root cause, implements corrective measures, and reviews for ongoing effective nonconformance resolution.

Simpletrak(R)

China Surgical Tools’ quality records are maintained in the web-based Simpletrak(R) system by ION Quality Systems. Data queries and detailed reporting functions facilitate China Surgical Tools’s continuous improvement. We encourage customers and vendors to access our QMS through our internet based Simpletrak(R) system and become part of the solution.

Inspection Instruments:

- Mitutoyo Crysta-Apex C 544 CNC coordinate measuring machine, w/ Renishaw MH20i probe. Axis travels 20” x 16” x 16”. Resolution 0.000004”.

- Hexagon Metrology PC-DMIS software. Provides for direct CMM inspection from imported solid models. Powerful, flexible reporting tools enable inspection and documentation of complex geometric tolerances.

- Mitutoyo Surf-Check Model 178602 profilometer

- Jones & Lamson Model TC-10 optical comparator, 10X and 20X magnification

- Stereo zoom microscopes, with 45X magnification and illumination for parts inspection.

- Granite surface plates of various sizes

- Full complement of hand-held measuring instruments including specialty micrometers

- Comprehensive set of ground and calibrated thread gauges, gauge blocks and pins

All measuring instruments calibrated by an independent lab traceable to NIST. Calibration records maintained as required by AS9100D and ISO9001 standards.