Citric Acid Passivation

As an ISO 9001 and AS9100 certified precision component manufacturer, China Surgical Tools’ citric acid passivation processing reflects the company’s commitment to minimizing our environmental impact and promoting best industry practices. With the increasing importance of medical instrument cleaning needs, our medical device passivation provides the necessary acid solution for cleaning and passivating stainless steel medical devices. Citric acid passivation for medical components plays a crucial role when high-performance and durability are standard requirements for a majority of medical devices.

Unlike nitric passivation, passivating with citric acid offers a number of benefits in addition to being much safer and environmentally friendly:

- Citric acid only removes iron without removing any other elements in the alloy.

- Citric acid does not introduce heavy metals or hazardous waste into the passivation tank solution.

- Citric acid yields excellent results without producing hazardous waste and no air pollutants.

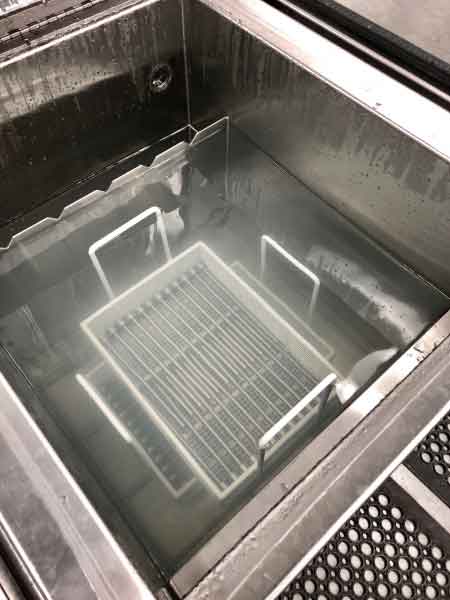

Our proven process emphasizes the importance of quality from start to finish, utilizing advanced Ultrasonic Cleaning Technology. We use only deionized water sources at each step of the cleaning cycle.

From thoroughly pre-cleaning parts to maximize passivation effectiveness, to multiple post passivation rinses for the prevention of water marks, our process is able to improve not only the appearance but corrosion resistance and longevity of stainless steel products for the medical, aerospace and high technology industries we serve.

The Citric Acid Passivation Process

While passivation occurs naturally on stainless steel alloys, this intrinsic passive layer can be compromised by contaminants (dirt, oil, grease) and the presence of free iron particles (microscopic particles that are worn off of the cutting tools and transferred to the surface of the steel) that parts are exposed to while on the shop floor. These non-visible particles prevent the stainless steel from forming a complete passive layer and can lead to rusting on the surface of the part.

Passivation is a chemical surface treatment that is designed to enhance corrosion resistance and reduce the impact of environmental exposure (such as water or air), by removing the particles of free iron that may have been deposited during the manufacturing process and allowing the stainless steel to return to its naturally passive state.

Benefits of Citric Acid Passivation

- Improves cleanliness by removing surface impurities and contaminants

- Improves the sterilization process for medical equipment

- Increases corrosion resistance

- Increases stainless steel quality in aerospace and military applications

- Helps improve and extend the product life

China Surgical Tools’ Citric Passivation Advantages

Our controlled chemistry and detailed recordkeeping allow for consistent and repetitively successful results while meeting all of the requirements of ASTM A967 and ASTM A380 standards. All of our processing equipment and measuring/testing devices are kept up to date on maintenance and calibration in accordance with ISO9001:2015 and AS9100D standards’ requirements.

Each passivation process is validated using copper sulfate testing and certified with a unique identifier traceable to the inspection and chemistry records specific to that passivation lot.

Here is an example of thePassivation Process Certificationwe provide our Medical customers.

Discuss Your Medical Device Passivation Needs with China Surgical Tools Today

With a commitment to high-quality medical device,

China Surgical Tools has the citric passivation experience to provide a complete solution for all your stainless steel medical device manufacturing needs.

Discuss your citric passivation needs with us or request a quote today.