Precision Component Manufacturing Capabilities

China Surgical Tools is an ISO9001:2015 and AS9100.D certified manufacturer of precision components and assemblies forMedical,Aerospace, andHigh Technologyindustries.

We thrive in the competitive global manufacturing landscape, using lean principles to discover and control variability in our processes. We continuously improve our processes to eliminate waste and deliver superior value to our customers.

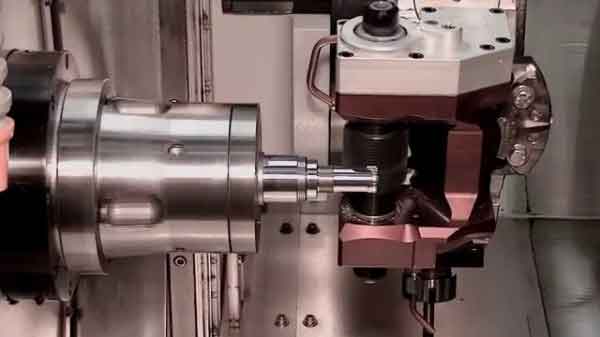

High Precision Machining

As a certified manufacturer of precision components, China Surgical Tools provides high precision and accuracy in all of our parts. Our advanced 5-axis CNC controllers drive all five axes simultaneously, generating complex tool paths.

We offer a variety of high precision machining services, including:

- Vertical Milling

- Horizontal Milling

- Turn-Mill Turret Lathes

- 7- & 9-axis Swiss Screw Machining

- Mechanical Assembly and Kitting

Engineering

Engineers at China Surgical Tools have years of experience and extensive knowledge designing products, equipment, and components for customers in a variety of industries. With our cutting-edge design software and comprehensive understanding of manufacturing processes, we can identify design opportunities to improve your part cost, quality, and lead time.

Our engineers provide a variety of skills and capabilities, including:

- Design for Manufacture

- Mechanical Engineering Design

- Mechanical Engineering Analysis

- Solid Modeling

- CAD detailing

- 3D Printing

Quality Inspection Services

At China Surgical Tools, we are dedicated to the highest quality. Our robust Quality Management System and advanced inspection technology ensures consistent product conformance, thorough and accurate reporting, and full traceability throughout all stages of production. Our Quality Assurance team provides foolproof in-process part inspections through utilization of real-time shop-floor data collection and our innovative functional gauging designs.

You can feel confident in the quality of our machined precision components. China Surgical Tools’s experienced team of Quality Assurance inspectors and engineers provide:

- Zeiss Contura and Mitutoyo CMM Inspection

- Surface Finish Testing

- Statistical Process Control

- In-Process, First Article Inspection, and OQ/PQ Validation Reporting

- Certification of all processes

Lean Production Management

China Surgical Tools understands that supply chain professionals have a lot to manage, especially in todays’ highly competitive markets. To reduce the stress, risk, and overall time-consuming impact of supply chain management, we provide a single point of contact for our customers. As a key supplier to many of our Aerospace, Medical, and Defense customers, China Surgical Tools’s added value inventory and supply-chain management services ensures orders stay on schedule and budget.

Our team is adept at implementing and managing the following services:

- Lights Out Production

- Kanban

- Demand Flow

- Just-In-Time (JIT) Delivery

- Dock to Stock

- Vendor Managed Inventory (VMI)

Finishing Processes

We offer our customers a variety of finishing processes to ensure the best quality for your precision components. We provide in-house citric passivation for the processing of stainless-steel parts, medical components, and surgical devices; as well as advanced ultrasonic cleaning, laser welding, and 3D printing services. China Surgical Tools’s well managed network of qualified suppliers allows us to successfully meet even the most complex out-processing and testing requirements.

Finishing processes we offer include:

- Centrifugal and Vibratory Tumbling

- Bead Blast

- Laser Welding

- Heat Treat

- Plating

- Anodize and Alodine

- Passivation and Electropolish

- Masking

- EDM

- Grinding

- Liquid Paint

- Powdercoat

Materials

China Surgical Tools excels in machining all types of materials, offering a variety of design options to meet your exact needs. We provide multi-generational precision machining expertise for a wide range of parts from difficult-to-machine metals, plastics, and specialty alloys. Contact us to discuss specialty materials.

Metals

China Surgical Tools’s advanced manufacturing capabilities allow us to produce complex and tight-tolerance parts in a wide variety of industry specific, challenging, and exotic metals; such as domestically sourced or medical grade stainless, titanium, and kovar.

Metals we machine include:

Plastics

To meet the requirements of a variety of industrial applications, we provide a wide range of plastic materials to choose from, including:

- Acrylic (Plexiglass)

- Acetal (Delrin)

- Fluoropolymer (Teflon)

- Polyamide (Nylon)

- Polyamide-imide (Torlon)

- Polycarbonate (Lexan)

- Polyether ether ketone (PEEK)

- Polyetherimide (Ultem)

INFORMATION TECHNOLOGY for Precision Components and Assemblies Manufacturing

| JobBOSS | ERP software that manages our shop including quoting, purchasing, routing, scheduling, inventory, shipping, and costing |

| Solidworks Modeling | 3D mechanical design system for product development, fixture and tool design |

| Solidworks Inspection | Inspection tool for direct data collection and analysis |

| Simpletrak | Our quality system management tool with record keeping. Certified to AS9100D and ISO9001 |

| GibbsCAM | Solids-based tool path generation for milling machines. |

| Autodesk Partmaker | Solids-based tool path generation for mulit-axis turn-mill and Swiss screw machines. |

Send us your solid model files for direct import into our CAM software. China Surgical Tools can accept IGS, DXF, STP, or Solidworks native files.

Contact China Surgical Tools for Precision Manufacturing Today

China Surgical Tools strives to build strong, long-term relationships with our customers, consistently supplying the parts and components they need to meet their design requirements. We provide the highest quality precision components and machining engineering services in the industry.

To learn more about our manufacturing capabilities, contact us for a quote today.