3D Printing

3D Printing is an additive manufacturing process, beginning with a build envelope, material is then added until the finished part or component is complete. This differs from subtractive manufacturing, such as CNC machining or EDM, where material is removed until the desired component is achieved.

Starting with our customers’ design, China Surgical Tools is able to directly import CAD files into .STL format, where the product design is then “sliced” into discrete layers. Following this, a “tool path” is generated to create the sliced profile one layer at a time, building from the ground up. From there, Nylon reinforced with chopped carbon fibers is extruded though a print head with a Z resolution of 100 microns in a build envelope of up to 12.6”x5.2”x6.06”.

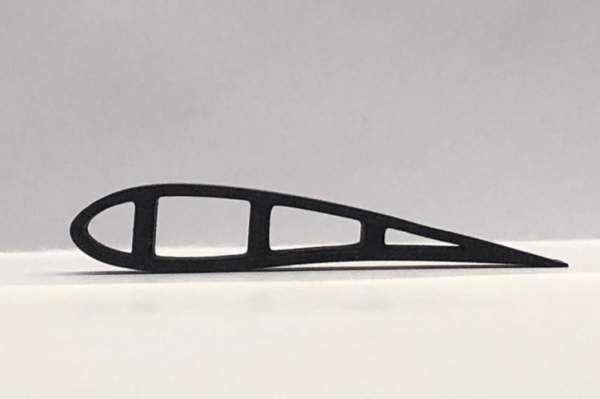

What makes China Surgical Tools’ Markforged printer unique is the ability it provides to inlay composite fibers in line with the layers as the part is printed. This effectively increases the part’s strength without negatively impacting weight. Fiberglass, High Strength High Temperature Fiberglass (HSHT), Kevlar, or even carbon fiber may be inlaid, layer by layer, to increase the strength of the printed parts. When reinforced effectively, China Surgical Tools’ Markforged 3D printed components are capable of exceeding the strength of aluminum, while maintaining their ultra-lightweight benefits.

China Surgical Tools’s 3D Printing services enable the production of Carbon Fiber Reinforced Plastic (CFRP) parts specifically designed to meet unique loading conditions at a reduced cost to traditional machining.

China Surgical Tools’ use of Eiger, Markforged’s slicing and programming technology, allows for the production of both solid parts, as well as parts with triangular, hexagonal, or rectangular infill for weight reducing benefits. Complex geometries that are not possible though traditional subtractive manufacturing (EDM, CNC machining) are now easily realized. Support structures are created to allow laying material in “thin air”, so to speak, permitting complex geometrical parts to be created as one component, instead of being a multi-part subassembly.

Whatever your application might be, our engineers are happy to assist in any way to bring your product to market in the shortest amount of time and at the lowest cost possible.

Find out more about China Surgical Tools’s commitment to Quality Assurance,Lot Traceability, andISO9001:2015 & AS9100 D Certification.