Precision CNC Machining

With decades of experience, China Surgical Tools has built a reputation as an industry-leading precision CNC manufacturer. Through our use of advanced technology and state-of-the-art equipment, we provide high-quality precision components and assemblies for our customer’s critical applications.

We offer a wide range precision manufacturing services, including CNC turning, CNC horizontal and vertical milling, and precision screw machining for short and long run production. Our machinists have the extensive experience, training, and specializations needed to machine even the most complex components.

Our CNC machining centers can produce high precision parts in a variety of materials, including stainless steel, aluminum, copper, nickel, and brass alloys, titanium, plastics, and other exotic materials. The materials we machine include:

CNC Manufacturing Expertise from China Surgical Tools

China Surgical Tools’s multi-generational industry-specific expertise, experienced machinists, and advanced manufacturing equipment allow us to provide our customers of all market sectors with the competitive edge needed to succeed.

China Surgical Tools is a leading precision manufacturing company across a wide range of industries, including:

We are constantly adopting and utilizing the most advanced machines, equipment, and technology on the market in order to ensure optimal efficiency, uniformity, and quality. Our team of highly skilled and experienced machinists, programmers, and engineers allow China Surgical Tools to consistently meet our customer’s high precision demands and exceed industry capabilities.

From precision CNC milled and turned parts, to highly detailed and complex components, we have the necessary equipment and industry experience to meet our customer’s expectations. We are committed to completing every project on time and at market competitive costs.

Our machined parts have been used in a variety of applications, including underwater video housings, where China Surgical Tools is able to supply aluminum housings, front plates, handles, and handle housings.

Advanced CNC Machining Equipment

Milling Machines

China Surgical Tools utilizes a variety of both horizontal and vertical CNC machine centers to produce high precision components quickly and accurately. Our CNC milling machines can hold tight geometric tolerances and critical dimensions. This allows China Surgical Tools to manufacture unique and complex parts for projects ranging from prototype qualification to high-volume production.

Our milling machines include advanced features such as multi-pallet management systems, cell control software, and Renishaw spindle probes for automatic tool path compensation to ensure precision and accuracy.

Our CNC milling machine center includes:

- 1 Matsuura H+300 PC11 Horizontal Mill. 20 hp, 20,000 rpm spindle. 20x20x20” axis travel, 11-pallet flexible cell system, 240-tool ATC. State of the art in production automation for horizontal machining - designed for low labor lights out operation!

- 1 Matsuura H+300 PC5 Horizontal Mill. 20 hp, 15,000 rpm spindle. 20x20x20” axis travel, 5-pallet flexible cell system, 240-tool ATC. Renishaw MP700 part probe and tool probe with break detection.

- 1 Makino a51-A60 Horizontal Mill. 30 hp, 12,000 rpm spindle. 22” x 22” x 20” axis travel, dual 400mm pallet changer.

- 1 Kitamura HX-250iF Horizontal 5-axis Mill. 10 hp, 15,000 rpm spindle. 12” x 12” x 12” axis travel, dual 250mm pallet changer. Ideal for parts with close tolerance complex geometries.

- 1 Kitamura 3XiF SparkChanger Vertical Mill. 15 hp, 20,000 rpm spindle. 30” x 18” x 18” travels, automatic pallet changer for maximum production up time.

- 1 Ganesh VFM2818 CNC Vertical Mill. 10 hp, 12,000 rpm spindle. 28” x 18” x 16” axis travel. Renishaw MP40 part probe. New in 2017!

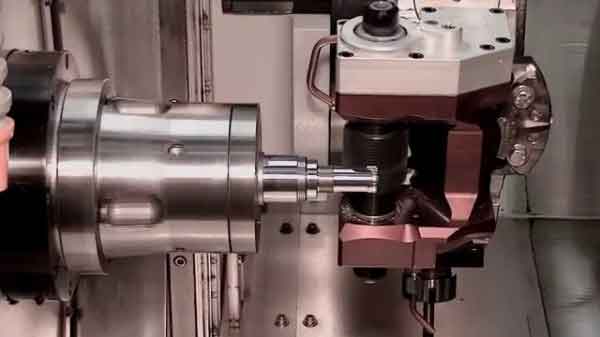

CNC Screw Machines

China Surgical Tools provides complex screw machining services to meet the diverse needs of our customers and fulfill the growing demand for high precision micro-parts. Our advanced CNC screw machine equipment ensures the most precise, efficient, and timely production of complex turned parts.

Screw machines provide the benefit of high precision with minimal downtime. China Surgical Tools’s precision screw machine centers help increase production efficiency by simultaneously moving both tool and material, and by utilizing secondary processing capabilities. This eliminates the need for additional operations and produces parts on time and within budget.

With our state-of-the-art technology and advanced machine centers, we can use a single setup to execute a series of multiple machining operations. Additionally, we also utilize automated bar feeding equipment and conveyor systems for rapid, continuous, and lights-out production.

Our CNC Swiss screw machine equipment center includes:

- 1 Tornos ST-26 CNC 9-axis Swiss Screw Machine. Simultaneous machining at 10 hp, 10,000 rpm C-axis front and rear spindles. Driven tools for milling complex features at both spindles. Automatic raw stock bar load/feeder and finished part ejector. 1000 PSI chilled coolant. 1” dia bar thru spindle.

- 5 Ganesh Cyclone 32CS 7-axis Screw Machine. Simultaneous machining on 10 hp, 6000 rpm C-axis front and rear spindles. 27 tools including driven face and side working tools at both main and sub spindles. 1.25” dia bar thru spindle. Automatic raw stock bar load/feeder and finished part ejector. New machines added in 2016, 2017, and 2019!

Advanced 5-Axis Precision CNC Machines

Advanced 5-Axis CNC machines provide the ability to easily and accurately create complex 3D surfaces. 5-Axis machines can produce complex parts and shapes of any size in a single setup, improving productivity, accuracy, and overall product quality and finish.

Ideal for challenging parts requiring the tightest tolerances and highest quality, our 5-Axis machines allow China Surgical Tools to do more with less; providing additional flexibility to accommodate customer requests by quickly and efficiently transitioning between jobs, helping save both time and money.

Our CNC 5-Axis precision machining center includes:

- 1 Chiron FZ12MT 5-axis Mill-Turn. 24,000 RPM 30hp tilting B-axis milling spindle. 48-tool ATC. 2-1/2” bar-fed C-axis lathe spindle holds workpiece. FANUC 31i-B5 CNC control with glass scale feedback enable full 5-axis milling with extremely high precision. Back-working NC pick off vise enables 6-sided machining to eject complete parts. New in 2019!

- 1 Ganesh Cyclone 52TTMY 8-axis Dual Spindle, Twin Turret CNC lathe. Simultaneous synchronous machining on 30 hp, 6000 rpm C-axis spindles. 16 tools on both turrets, all can be driven by 7.5 hp servo motors. 1000 PSI coolant thru both turrets.

Information Technology and Software for CNC Machining

China Surgical Tools’s advanced technology and software resources allow us to design, program, and inspect complex part geometries directly from our customer’s solid model part files. This enables us to produce fast, repetitive production and inspection at a low cost.

China Surgical Tools’s information technology and software systems include:

| JobBOSS(R) | ERP software that manages our shop including quoting, purchasing, routing, scheduling, inventory, shipping, and costing |

| Solidworks(R) Modeling | 3D mechanical design system for product development, fixture and tool design |

| Solidworks(R) Inspection | An inspection tool for direct data collection and analysis |

| Simpletrak(R) | Our quality system management tool with record keeping. Certified to AS9100D and ISO9001 |

| GibbsCAM(R) | Solids-based tool path generation for milling machines. |

| Autodesk Partmaker(R) | Solids-based tool path generation for mulit-axis turn-mill and Swiss screw machines. |

Contact the Precision CNC Machining Experts at China Surgical Tools

As an ISO9001:2015 & AS9100D certified precision manufacturer, China Surgical Tools is dedicated to rigorous quality control, continuous process improvement, and thorough document control at every stage of production. Strict quality assurance measures ensure that every precision CNC machined component conforms to even the tightest tolerances and highest quality standards.

Our dedication to Quality Assurance, Lot Traceability, and ISO9001:2015 & AS9100 D Certification reflects a commitment to our customers. We are a precision CNC manufacturer that you can trust for your next custom CNC machining project.

Contact China Surgical Tools for all your precision CNC machining needs today.